combine up to 7 multi-kw Lasers: that’s what we call « high power »

The most cost effective way to achieve multi-kw level

Combining multiple laser sources can be tricky…

When combining together multiple high-power fiber laser sources, a lot of details must be taken care of. In addition of the challenge of the combiner itself, fiber handling can lead to un-efficient power transfer to the delivery cable which could eventually lead to overheating and failure.

Our laser combiners were designed and optimized based on ITF Laser Engine technology to provide the best performances. However, we are using the most common fiber used for kW-rated and above fiber lasers which makes our laser combiner compatible with most fiber laser manufacturer.

many attempts of combining multiple fiber laser sources are inconclusive. Why?

As the power of each laser module increases to multi-kW level, the slightest power loss will need to be managed so that overheating is kept to minimum. Combining high power together is not a simple task and many details need to be taken care of. By using just the combiner itself, you will have to handle excess power and fiber handling to get the proper functionality of the combiner.

« What you really need is the most power, usable right away. let us handle the link between lasers and the final output. »

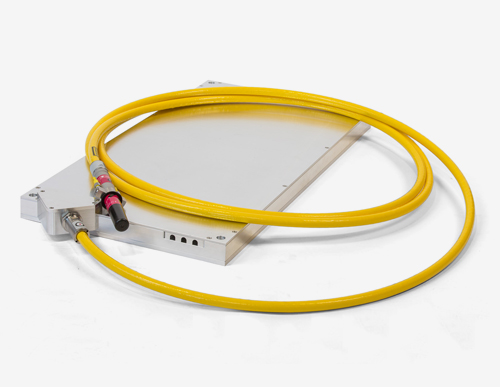

A laser combiner compatible with industry standards and usable with itf’s own laser engines for less puzzles and headaches

Even though the working principle is simple, the devil is in the details… we took care of the devil…

With the integrated solution for the laser combiner provided by ITF, the only thing you will have to worry about will be to splice your laser sources and the delivery cable in the adapted splice tray section. The laser combiner solution integrates Cladding Power Strippers as well as temperature monitoring at critical locations which will provide an extra layer of control to protect your laser system.

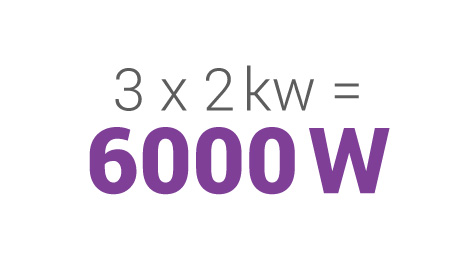

Let’s say you need a 6000 W output laser system …

What would be the more effective solution?

To get a 6 kW solution you will need to get 6 x 1 kW laser engines and a 6 x 1 laser combiner from availability on the market. This solution is very expensive since you have to acquire 6 individual units and a minimum of 6 input port combiners.

With ITF laser combiner solution, you can use 3 x 2 kW fiber laser and combine them with a 3 x 2 kW laser combiner: less bulky, less units, more cost efficient…

Change the laser combiner for a 7 x 2 kW and you now have a 14 kW solution