ITF’s Fiber Bragg Grating reflectors: Reflect the power of your system!

NO wonder OUR FBG mirrors gets you the best performance

Our Fiber Bragg Grating reflectors are made using a robust process developed over the years for different types of fibers, designed with the specific needs of high power fiber laser manufacturers in mind. They feature a low thermal slope and tight wavelength matching, ideal for kW level laser systems, with a standard pump power handling of up to 3kW. They can be supplied simply recoated with our robust low index polymer recoating process or packaged inside our long-time proven high-power package.

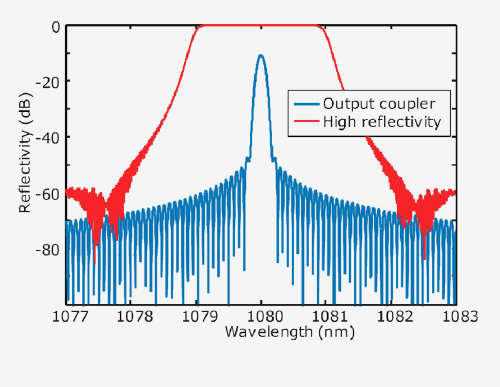

They can be written on an extremely wide range of fibers, from industry standards to completely custom fibers, to precisely match the gain fiber you’re using. Our process is also very customizable in terms of central wavelength and spectral width for both the High Reflector and Output Coupler of an FBG pair. Contact-us for any custom request.

« Reliable fbg mirrors for your optical cavity»

Low volume R&D project?

Very high volume for mass production?

We’re experts in both!

There are multiple parameters that will make or break the design of a fiber laser system. For the reflectors of your laser cavity, ITF’s FBGs will give you the best performance with the specifications you ask for. Because of our well-controlled FBG writing process you can benefit of our “self-matching” FBGs, with this approach you won’t have to question whether the two FBGs for your laser cavity will be a match.

Simplify your assembly by using TFBG…

Have your FBG High Reflector part of the pump combiner

ITF unique approach can write the FBG on the output fiber of the pump combiner. That way, you don’t need to splice your combiner to the FBG which saves you assembly time and increase the reliability of your laser assembly. This is one splice less to worry in your assembly. Furthermore, ITF offers a 5% discount when you by the integrated solution compare to separate components.

ITF’S FBG mirrors: enables high power applications all over the world

Much power will be seen by the FBGs, the High Reflector need to handle all the pump power from the cladding in a co-pump cavity. For this, the recoating process needs to be perfect. ITF’s manufacturing process assures that temperature elevation is kept at a minimal value. In fact, for some fibers, High Power test of recoated FBG, shows absolutely no temperature elevation with 300 Watts of pump power when measured without active cooling.

On the other end, the Output Coupler (or low reflector) will be subject to the full power of the laser output, therefore the FBG needs to be extremely stable. Here again, high power test assures that thermal slopes will be kept at an acceptable value when the FBG is properly cooled.

Finally, we recommend that the two FBGs be mounted close together to minimize differential thermal drift which would in turn create a differential spectral drift. Nevertheless, our “self-matching” approach allows for slight variation and assures the two FBGs “sees” each-other at all time.